Introduction

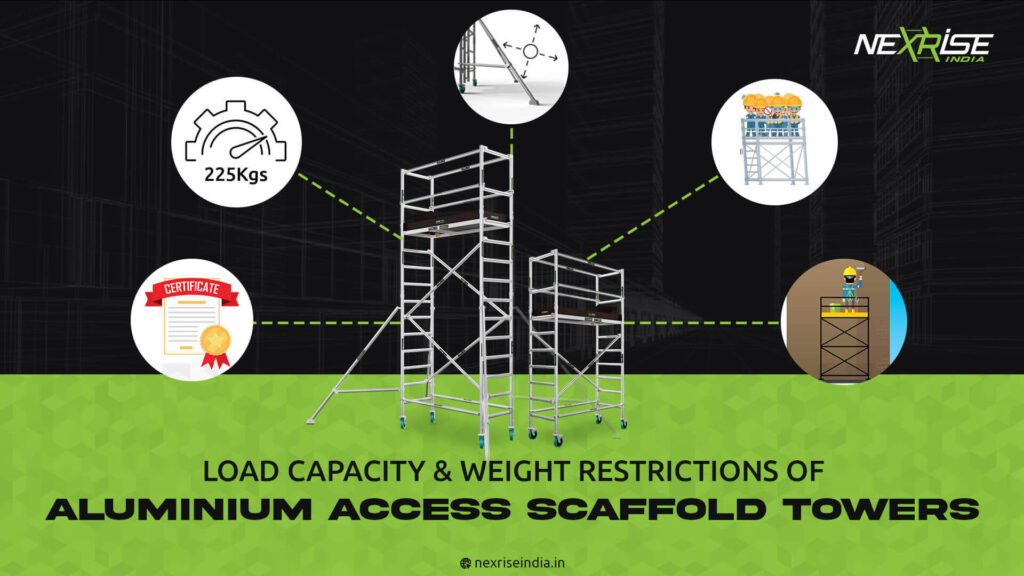

Understanding the load capacity and weight restrictions of aluminium access scaffold towers is essential for ensuring safety, efficiency, and regulatory compliance. Overloading a scaffold can lead to structural failures, accidents, and costly project delays. Businesses must adhere to industry safety standards and local regulations to mitigate such risks. At Nexrise India, we provide high-quality, certified aluminium scaffolding solutions that meet required safety standards, ensuring reliability and durability for various industrial and commercial applications.

Key Factors Affecting Load Capacity

Material Strength & Design

Aluminium scaffolds are widely preferred for their lightweight yet strong construction. Unlike traditional materials like steel, aluminium offers an optimal balance between portability and durability. The strength of an aluminium scaffold depends on the grade of aluminium used, the structural design, and the manufacturing quality. High-strength alloys are commonly used to enhance durability and load-bearing capacity. The design features, such as cross-bracing, reinforced joints, and wide bases, play a crucial role in distributing weight efficiently. Moreover, scaffolding that complies with established safety standards is tested to ensure superior performance under heavy loads, making it a reliable choice for various applications.

Key benefits of aluminium scaffolds include:

- Lightweight construction – Easier to transport and assemble.

- Corrosion resistance – Long-lasting and suitable for outdoor applications.

- High load-bearing strength – Ensures safety under different working conditions.

Types of Loads and Their Impact

A scaffold tower experiences different types of loads, all of which influence its weight restrictions and safe working limits. Dead load refers to the weight of the scaffold structure itself, including platforms, braces, and additional structural components. Live load consists of the combined weight of workers, tools, and materials placed on the scaffold during use. Environmental load accounts for additional forces exerted by external factors such as wind, rain, and vibrations, which can affect stability. Understanding these different types of loads is essential for ensuring that a scaffold is used within its prescribed limits. When any of these loads exceed the design capacity of the scaffold, it compromises stability and increases the risk of failure.

To manage load limitations effectively:

- Ensure even distribution of weight across the scaffold platform.

- Avoid sudden impacts or excessive movement that can destabilise the structure.

- Regularly inspect scaffolds for signs of wear, damage, or overloading.

Height and Stability Considerations

The height of a scaffold tower directly affects its ability to support weight. As a scaffold becomes taller, its centre of gravity shifts, which can impact stability. To counteract this, taller scaffolds require a wider base to ensure they remain upright and steady under load. Additional bracing and anchoring mechanisms are often necessary to reduce sway and enhance structural integrity. Another important factor is the load capacity per level, as higher scaffolds generally support less weight per platform to maintain safety. Workers should always consider the working height and corresponding load restrictions before assembling and using an aluminium scaffold tower to avoid potential hazards.

Best practices for scaffold stability include:

- Using outriggers or stabilisers for additional support.

- Secure the scaffold to a solid structure when working at significant heights.

- Avoid uneven ground for assembly to prevent tilting or imbalance.

Platform Load Ratings and Their Importance

Scaffold platforms are classified based on their intended use and maximum load capacity. Light-duty scaffolds typically support up to 120 kg per square meter and are ideal for inspection and light maintenance tasks. Medium-duty scaffolds, supporting up to 240 kg per square meter, are suited for applications such as painting, electrical work, and minor repairs. Heavy-duty scaffolds, capable of supporting up to 360 kg per square meter, are designed for industrial applications, masonry, and tasks requiring extensive material handling. Selecting the right classification based on the task at hand ensures a safe working environment and prevents structural overloading. It is also important for workers to evenly distribute weight across the platform to prevent instability and excessive strain on specific scaffold sections.

Guidelines for using scaffold platforms efficiently:

- Choose the correct load rating for the type of work being performed.

- Never exceed the specified weight limits outlined by the manufacturer.

- Check for wear and tear on planks and supports before use.

Compliance with Indian Safety Standards

Ensuring that scaffolding adheres to safety regulations is critical in preventing workplace accidents. In India, scaffold load capacities are governed by specific standards, including IS 2750:1964, which outlines safety requirements for scaffolding in construction and industrial applications, and IS 1161:2014, which defines structural specifications for tubular scaffolding systems. The Factories Act of 1948 further mandates the use of secure work platforms and the adherence to load capacity limits to ensure worker safety. In addition to Indian standards, global safety regulations such as OSHA (USA) and BS EN 1004 (Europe) offer further guidance on scaffold safety and usage. Nexrise India ensures that all scaffolding products comply with both local and international standards, providing clients with reliable and safe scaffolding solutions for a variety of industries.

Key legal requirements include:

- Adhering to IS 2750:1964 safety standards for scaffold design and use.

- Following the Factories Act of 1948, to ensure workplace safety measures.

- Complying with OSHA and BS EN 1004 for international regulatory alignment.

Conclusion

Maintaining proper load capacity in aluminium access scaffold towers is essential for worker safety, equipment longevity, and regulatory compliance. Understanding the different types of loads, stability factors, and platform classifications helps businesses make informed decisions regarding scaffold usage. Overloading scaffolds can result in serious accidents, making it imperative to follow manufacturer guidelines and local regulations. Nexrise India offers certified aluminium scaffolding solutions that align with Indian and global safety standards. Our expert team ensures that you receive the right scaffolding system tailored to your project’s needs, ensuring a safe and efficient work environment at height. For high-quality aluminium scaffolding solutions, reach out to Nexrise India today and secure a safe and productive workspace for your operations.