Scaffolding is a critical component in construction and maintenance projects, providing a stable platform for workers to perform tasks at heights. However, the same structure that enhances safety during assembly and use can pose serious risks if not disassemble scaffolding correctly. Improper dismantling of scaffolding can lead to accidents, injuries, or even fatalities. Understanding the correct procedures and safety measures is essential for protecting workers and ensuring a safe job site by properly disassemble scaffolding without risk.

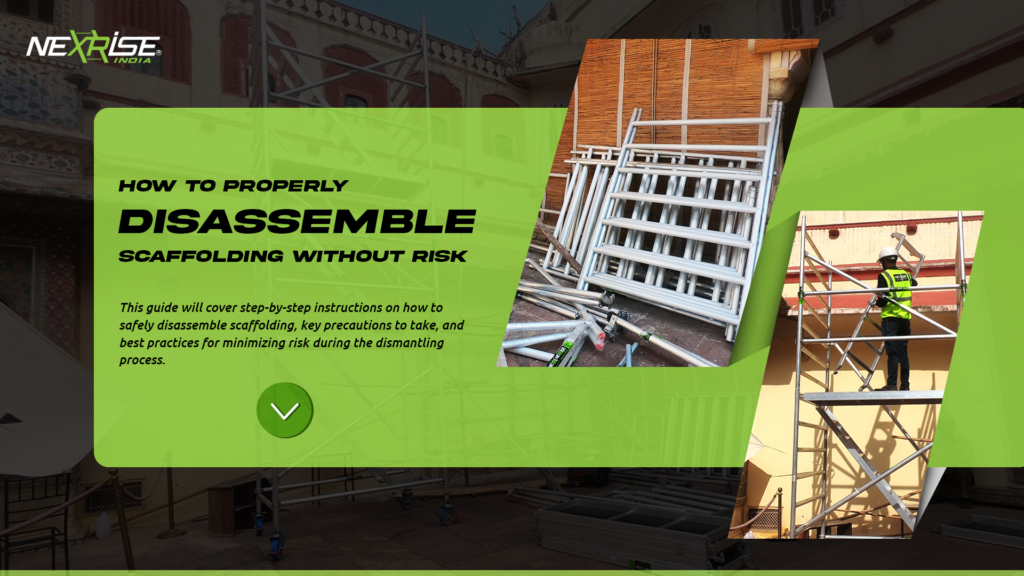

This guide will cover step-by-step instructions on how to safely disassemble scaffolding without risk, key precautions to take, and best practices for minimizing risk during the dismantling process. Whether you are working on a residential project or a large commercial site, the principles discussed here will help ensure that scaffolding disassembly is performed efficiently and without incident.

Why Proper Scaffolding Disassembly is Crucial

Before diving into the steps of disassemble scaffolding without risk, it’s important to understand why taking time and care during this process is essential:

1. Preventing Falls and Accidents

Many scaffolding-related accidents occur during disassembly, often due to improper procedures or rushing. Falling from heights or being struck by falling materials are common hazards when dismantling scaffolding.

2. Avoiding Structural Instability

Scaffolding is built to be stable when fully assembled. However, as it’s dismantled, certain sections can become less stable. If not done methodically, the structure may collapse, putting workers at risk.

3. Preserving Equipment

Disassembling scaffolding properly helps ensure that the components remain in good condition for future use. Mishandling the structure during disassembly can damage parts, leading to costly repairs or replacements.

Step-by-Step Guide to Disassemble Scaffolding without risk

Step 1: Planning and Preparation

The first step in any scaffolding disassembly project is thorough planning and preparation. This involves assessing the worksite, understanding the scaffold structure, and ensuring the right team is in place.

- Conduct a Risk Assessment: Before starting the disassembly process, perform a detailed risk assessment of the scaffolding setup. Identify any potential hazards, such as uneven ground, strong winds, or obstacles near the structure.

- Assign Trained Workers: Only workers who are trained in scaffold disassembly should be involved in the process. They should be familiar with the specific type of scaffolding in use, as different types (e.g., supported, suspended, mobile) have unique disassembly requirements.

- Prepare Safety Gear: Ensure all workers wear appropriate personal protective equipment (PPE), including hard hats, safety harnesses (if working at significant heights), gloves, and non-slip boots.

- Clear the Area: Before starting, clear the area surrounding the scaffold. Remove any debris, tools, or materials that could cause a tripping hazard or be affected by falling scaffolding parts.

Step 2: Inspect the Scaffolding Before Disassembly

Inspect the entire scaffold structure to ensure it’s in good condition and ready for disassembly. Look for any damage, wear, or looseness in the components that could complicate the process. Key areas to inspect include:

- Braces and Frames: Check for any damage to the braces, frames, or poles that may affect stability.

- Planks and Platforms: Ensure that all planks and platforms are secure and in good condition. Remove any loose or broken planks before starting the disassembly.

- Ties and Anchors: If the scaffolding is tied to a building or structure, check the condition of the ties and anchors. These will need to be safely removed during disassembly.

Step 3: Remove Accessories and Loose Materials

Begin the disassembly by removing any accessories or loose materials from the scaffold. This includes guardrails, toe boards, ladders, and safety netting.

- Guardrails and Toe Boards: Carefully detach all guardrails and toe boards from the structure. Guardrails are critical for worker safety during use but can become dangerous obstacles during disassembly if left in place.

- Ladders: Take down any ladders attached to the scaffolding. Ensure workers have an alternative safe method for accessing the remaining parts of the scaffold.

- Loose Materials: Clear the platforms of any tools, materials, or debris. Leaving these items on the scaffold during disassembly can lead to slips, trips, or falling objects.

Step 4: Dismantle the Scaffolding Platforms

Once the accessories and loose items are removed, the next step is to dismantle the scaffolding platforms. This step should be done methodically, starting from the top and working downward.

- Work from the Top Down: Always begin disassembly at the highest level of the scaffold and work your way down. Never remove lower sections while upper sections are still in place, as this could destabilize the entire structure.

- Remove Planks One by One: Carefully lift and remove each plank from the platform. Workers should avoid standing directly on planks while they are being removed, as this increases the risk of falling. Use appropriate lifting techniques to avoid straining or dropping the planks.

- Lower Materials Safely: Use a hoist or mechanical lifting device to lower planks and materials to the ground safely. Avoid dropping or tossing materials, as this can create a hazard for workers below.

Step 5: Dismantle the Scaffolding Frames and Braces

After the platforms are removed, begin taking down the frames and braces. This step requires careful attention to maintaining the stability of the scaffold as sections are removed.

- Maintain Stability: Ensure that the structure remains stable by removing one frame or section at a time. It’s essential to never remove too many braces or frames at once, as this could cause the remaining structure to collapse.

- Use Proper Tools: Dismantle the braces and frames using the appropriate tools, such as wrenches or clamps. Avoid using makeshift tools that could damage the components or compromise safety.

- Lower Frames to the Ground: Just as with the platforms, lower frames and braces to the ground carefully using a hoist or similar equipment. Dropping these items can cause damage or injury.

Step 6: Conduct a Final Inspection and Cleanup

Once the scaffolding is fully disassembled, conduct a final inspection of the worksite.

- Check for Remaining Materials: Ensure all scaffolding components have been removed from the site and stored properly for future use.

- Inspect for Hazards: Look for any hazards that may have been created during disassembly, such as uneven ground or leftover debris. Address these issues before allowing workers or equipment back into the area.

- Store Equipment Safely: Store all scaffolding components in a safe, organized manner to prevent damage and make future use easier.

Key Safety Tips for Disassemble Scaffolding without risk

To ensure a safe and efficient disassembly process, keep the following safety tips in mind:

- Never Rush the Process: Rushing through disassembly increases the likelihood of mistakes and accidents. Take your time to ensure that each step is performed correctly.

- Maintain Communication: Good communication is critical during disassembly. Workers should be aware of each other’s movements and actions to avoid accidents.

- Use Fall Protection: If working at heights, always use appropriate fall protection, such as harnesses and lanyards.

- Follow Manufacturer Guidelines: Always follow the scaffolding manufacturer’s instructions for disassembly. Different systems may have specific disassembly procedures.

- Monitor Weather Conditions: Avoid disassembling scaffolding in adverse weather conditions, such as high winds or rain, which can increase the risk of accidents.

Conclusion

Disassemble Scaffolding without risk is just as important as erecting it. By following a systematic process, adhering to safety guidelines, and ensuring that only trained workers handle the disassembly, you can significantly reduce the risk of accidents using Scaffolding and ensure a smooth, hazard-free project. Taking the time to do it right protects both your team and your equipment, ensuring that scaffolding can be reused safely in future projects.

By considering the specific requirements of your project and choosing a scaffold that fits those needs, you can enhance both safety and productivity on the job.

If you want to buy or rent our aluminium scaffolding. Feel free to call us!

Read more: What are Scaffold Tagging and Types?