When choosing scaffolding for construction or maintenance projects, the material plays a vital role in determining safety, efficiency, and cost-effectiveness. Aluminium scaffolding has gained popularity over mild steel (MS) scaffolding due to its numerous advantages. In this blog, we will explore the top 10 benefits of aluminium scaffolding and why they are an excellent choice for modern construction needs.

Why Material Matters in Scaffolding

The choice of material directly impacts the durability, ease of use, and overall performance of scaffolding systems. Aluminium scaffolding is increasingly favored due to its lightweight, corrosion resistance, and versatility, making it a superior alternative to traditional MS scaffolding. While MS (mild steel) scaffolding has been a reliable choice for years, the advancements in aluminium technology now offer unmatched benefits that cater to the needs of modern construction.

1. Lightweight Yet Strong

Aluminium scaffolds are significantly lighter than MS scaffolds without compromising on strength, weighing up to 50% less. For instance, a typical aluminium scaffolding can be easily transported and assembled by a two-person team, whereas MS scaffolds often require additional manpower and equipment due to their heavier weight. This makes transportation and assembly much easier, especially on projects where frequent repositioning is required.

Key Points:

- Up to 50% lighter than MS scaffolding (mild steel) .

- Easier to carry and maneuver, reducing physical strain.

- Reduces labor fatigue and time spent on setup, increasing efficiency.

- Ensures that even smaller teams can handle setup and transportation with ease.

2. Corrosion Resistance

Unlike MS scaffolds, rust-resistant scaffolding for outdoor use, like aluminium scaffolding, do not rust, making them ideal for outdoor and humid environments. This advantage ensures that they maintain their structural integrity over time, even in challenging weather conditions.

Key Points:

- Long-lasting in adverse weather conditions, such as rain and snow.

- Minimal maintenance requirements compared to rust-prone MS scaffolding.

- Perfect for coastal and industrial settings where exposure to moisture and chemicals is common.

- Eliminates the need for additional anti-rust treatments, reducing upkeep costs.

3. Enhanced Portability

The lightweight nature of aluminium makes it highly portable, especially for projects requiring frequent relocation of scaffolding. This feature is particularly useful for contractors working on multi-site operations.

Key Points:

- Easily transported between sites with minimal effort.

- Simplifies setup in confined spaces and urban areas.

- Ideal for small to medium-scale projects and quick maintenance tasks.

- Reduces logistical challenges, ensuring smoother project execution.

4. Cost-Effective in the Long Run

While the upfront cost of aluminium scaffolding might be higher, its durability and low maintenance lead to long-term savings. For businesses looking at overall cost efficiency, aluminium scaffolding are a worthwhile investment.

Key Points:

- Extended lifespan reduces frequent replacement costs.

- No additional expenses for anti-rust treatments, unlike MS scaffolding.

- Lightweight design reduces transportation costs over time.

- Enhances productivity, leading to better ROI on projects.

5. Versatile Applications

Aluminium scaffolding is suitable for a wide range of applications, from construction to maintenance and even rental businesses. Its flexibility allows it to meet the demands of diverse industries.

Key Points:

- Compatible with various heights and structures, from small homes to large commercial buildings.

- Adaptable for indoor and outdoor use, offering unmatched convenience.

- Frequently used in industries like aviation, warehousing, and building maintenance.

- Highly sought after for rental services due to its ease of use and durability.

6. Quick and Easy Assembly

With modular designs and lighter components, quick-setup aluminium scaffolding is faster to assemble and dismantle, ensuring efficiency on tight deadlines. This feature is crucial for projects with tight deadlines.

Key Points:

- Reduces labour hours significantly, saving time and resources.

- Minimal tools are required for assembly, simplifying the process.

- Ideal for time-sensitive projects where efficiency is paramount.

- Ensures quick adaptability to changing project needs or site conditions.

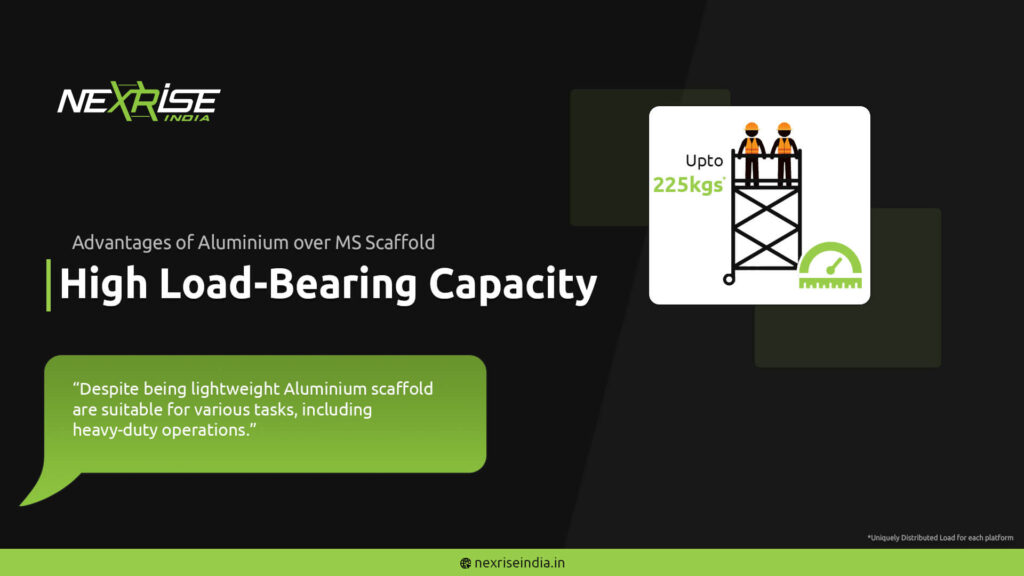

7. High Load-Bearing Capacity

Despite being lightweight, aluminium scaffolds offer excellent load-bearing capacity, making them suitable for various tasks, including heavy-duty operations. For example, aluminium scaffoldings are frequently used in industries like aviation maintenance, where they support technicians and their tools securely, or in warehousing for high-reach shelving installations.

Key Points:

- Supports multiple workers and tools simultaneously without compromising stability.

- Suitable for heavy-duty tasks, such as construction and industrial maintenance.

- Ensures safety and stability even at higher elevations.

- Meets stringent safety standards for load handling.

8. Eco-Friendly

Aluminium is a recyclable material, making aluminium scaffolding an environmentally conscious choice. Its sustainable nature aligns with global efforts toward greener construction practices.

Key Points:

- Promotes sustainability in construction by reducing waste.

- Reduces environmental impact compared to non-recyclable materials.

- It can be reused across multiple projects, reducing the demand for raw materials.

- Contributes to eco-friendly certifications for construction projects.

9. Sleek and Modern Design

The sleek appearance of aluminium scaffolding is visually appealing and aligns with modern construction aesthetics. It adds a professional touch to project sites.

Key Points:

- Complements high-end projects with its polished look.

- Reflects professionalism and innovation in construction practices.

- Clean and polished appearance compared to rust-prone MS scaffolds.

- Enhances the visual appeal of construction sites, especially for urban projects.

10. Safer to Use

Aluminium scaffolding often come with advanced safety features, enhancing worker security and minimizing the risk of accidents.

Key Points:

- Anti-slip platforms and guardrails provide added safety.

- Better stability due to lightweight yet robust construction.

- Reduced risk of accidents compared to heavier MS scaffolds.

- Adheres to international safety standards, ensuring worker protection.

Conclusion: The Clear Winner

Aluminium scaffolding stands out as the superior choice over MS scaffolding due to its lightweight, corrosion resistance, and overall efficiency. Choosing the best aluminium scaffolding for construction projects ensures optimal performance and cost-effectiveness, making it the go-to option for contractors worldwide. It offers long-term savings, versatility, and enhanced safety, making it ideal for modern construction and maintenance projects. Investing in aluminium scaffolding ensures better performance, safety, and sustainability—a smart decision for any business or project manager. With its combination of strength, durability, and eco-friendliness, aluminium scaffolding is the future of construction support systems.